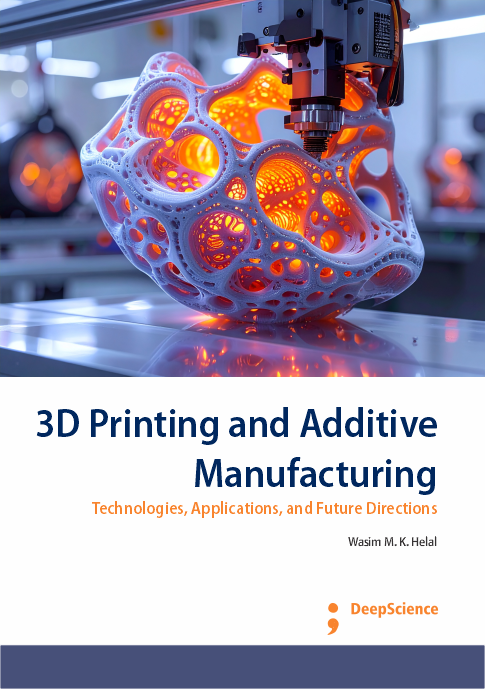

3D Printing and Additive Manufacturing: Technologies, Applications, and Future Directions

Keywords:

Additive Manufacturing, 3D Printing, Rapid Prototyping, Digital Fabrication, Automotive, Biomedical, SustainabilitySynopsis

3D printing or additive manufacturing has become a revolutionary technology that is expected to disrupt a lot of industries. A simple tool for rapid prototypes grew up into the manufacturing method we have now developed. It is possible to generate complex shapes and functional components almost of any kind of material, enabling a new freedom in design and manufacturing.

This book is a comprehensive guide to the wide and diverse world of 3D printing and related techniques. We’ll take a look at how it’s being used in applications today, the design considerations you should keep in mind, and how this new technology could continue to evolve in the future. We want to provide you with a comprehensive overview of how 3D printing is molding sectors and the world at large.

In order to really get a sense of the significance of 3D printing, one must relate it to the context of technology and history that it has emerged from. The idea of layer wise material buildup, a fundamental aspect of additive manufacturing, originated in the 1980s as an approach to rapid prototyping. Prior to 3D printing, rapid prototyping was a time-consuming and costly affair due to the drawbacks of sharp edged tools, subtractive cutting methods, the frequent human errors, manual skill requirements, and lathe notching among the subtractive cutting methods, that are detrimentally persistent in these technologies, resulting in limited efficiency and tight dimensional tolerances, a significant amount of waste material, and labour-intensiveness. 3D printing was a game changer, it allowed designers and engineers to a produce precision, intricate models straight from a digital file cutting time and costs in half.

More and more, 3D printing has become part of the production shop floor and research laboratory, not to mention kitchen table. Photo One great benefit of this technology is that it can process plastics, metals, ceramics, biomaterials and food. The ability to generate custom products where there is demand, without expensive molds or tools, has opened up vast fields of opportunity in aerospace, medicine and fashion. This flexibility makes businesses can tailor themselves in a personal level – therefore easier to be creative. And pot calling kettle, it’s not hyperbole to say that 3D printing is transforming manufacturing from a world where things are made to one where they are created, in which objects of every summer and continent (from design classics to human body parts) do not come into being end masse but custom-erupt in orgy of form and (your) function.

By journeying through the current and future potential of 3D printing, this book will launch you into the innovative and emergent world of 3D printing. We’ll examine in much more detail how 3D printing is already revolutionizing traditional manufacturing. This capability results in rapid iterations of designs, shorter lead times, and less waste, leading to an overall more efficient and sustainable process. Such advances do not only lead to cost reductions, but also support sustainable developments considering that the additive manufacturing techniques usually demand less material and energy compared to conventional manufacturing.

The most exciting possibility with 3D printing is the opportunity to democratise manufacturing. Small companies, entrepreneurs and inventors now have access to production capability that, in the past, only large budgeted, specialty facility serviced corporations did.

And then also 3D printing is, I feel like, taking a bit sort of like some of the extremes of what we can do with design even too. It’s allowing new possibilities in design that in many cases were not achievable before, letting designers push around more extreme forms and structures that do more than simply look cool. Cost of complex production: Traditional manufacturing does a bad job of enabling the production of complex products. Products are designed according to the limitations of the production process. Additive manufacturing, on the other hand, facilitates complex internal structures, lightweight lattice systems as well as functional integration, many of which have been, at best, impossible to achieve or, at worst, laughably expensive to even consider. That’s forcing engineers and designers to start by rethinking how you design in the first place, with new materials and hybrid solutions that can combine many functions in one component.

Medical applications of 3D printing have been one of the most rapidly developing areas. Patient-specific implants, prosthesis, surgical jigs and perhaps even bioprinting of tissues are a fantastic advancement in patient care. The technology provides patients customised treatment options according to the specific anatomy, enhancing outcomes and quality of life. Living cells and organs have naturally been an exciting frontier for research, which can potentially revolutionize transplantation and regenerative medicine in the future.

Moreover, with the increasing use of 3D printing, ethical and environmental aspects should be responsibly considered. The possibility of IPR disputes, counterfeit products and non-regulated manufacturing all begs questions of governance and responsibility. And just as additive manufacturing lessens waste, energy consumption is still high on some of the processes, which demands constant innovation in sustainable practices and materials.

Looking into the horizon, 3D printing looks diverse and exciting. I think we will also see the rise of another trend, such as multi-material printing, an increased focus on advanced robotics (technology integration), AI driven design and process optimization, and growing reach of bioprinting and nanomanufacturing. The intersection of these technologies is projected to enable new products and markets, including smart manufacturing spaces and personalized consumer goods that would adapt to their users on the fly.

This book is for anyone interested in the future of technology, including (but not limited to) those that identify as an industry practitioner, academic, student and/or casual observer. We hope to offer a balanced perspective, including the technical explanations as well as how they work, and share examples and experiences from the leading pioneers. In the process of taking this holistic approach, you will also develop a profound understanding of why 3D printing is more than simply a tool, it can be an indispensable engine of innovation. It could revolutionize how we live, work and create.

So, at last, the tale of 3D printing is one of blistering change, endless invention and cube-rattling power. From concept models to manufacturing tools and metal or human cells, this tech knows pretty much its only limit is your imagination. By the end of this article you will have plenty of background to understand where it's coming from, see where it's going, and even get some of the itch to roll up your sleeves and get busy with it, as it will be sure to have to interesting insights to spring on us in the coming years.

This book has been written in a way that’s is accessible to all, regardless of knowledge. In the introduction, the historical evolution and technological importance of 3D printing are put forth. Chapter: 1 Sub-chapter: 1 Description The basics What is 3D printing The history of 3D printing Types of 3D printing technology The 3D printing process Chapter 2 discusses materials in 3D printing including standard materials, new developments and materials selection criteria by application. Chapter 3Discusses the multiple ways 3D printing is being used in key vertical markets such as medical, aerospace, automotive, consumer goods, and education. Chapter 4 combines insights into how things work with a preview of the design process before describing CAD software, a high-level guide to 3D design best practices, and advice for overcoming design challenges. Chapter 5 looks to the future, analyzing new developments, 3D printing as related to artificial intelligence, and the sustainability of 3D printing. Chapter 6 examines the business impact, cost-benefit analysis, success stories, and challenges faced by the business. Last, but not least, Chapter 7 discusses the regulatory and ethical aspects of intellectual property, safety standards and the societal impact of 3DP. We wrap up in the conclusion discussing some implications for transformative possibilities of this technology.

References

3DPrint.com. (2023, March 1). Ethical 3D Printing: 9 Ways 3D Printing Could Aid Criminals. Retrieved from https://3dprint.com/298073/ethical-3d-printing-9-ways-3d-printing-can-be-used-for-crime/

A. Hariharan, A. Kavitha, Rajapandian Siva Ganesa Karthikeyan, Ravinarayanan Haribalaganesh, S. Rajkumar. "chapter 16 Enhancing Molecular Comprehension in Medical Education Through 3D-Printed Models as a Digital Pedagogy Approach", IGI Global, 2025

Abeles, Harold F., Custodero, Lori A.. "Critical Issues in Music Education", Critical Issues in Music Education, 2021

Alberto Boretti. "Metal additive manufacturing for internal combustion engine components: a narrative review of applications, materials, processes, challenges, and future directions", The International Journal of Advanced Manufacturing Technology, 2025

Amit Aherwar, Catalin I. Pruncu, Binnur Sagbas, Luciano Lamberti. "Advanced Technologies for Sustainable Biomedical Applications", CRC Press, 2025

Andi Alijagic, Damir Suljevic, Magnus Engwall, Eva Särndahl. "3D printing: Balancing innovation for sustainability with emerging environmental and health risks", iScience, 2025

Angela Daly. "Socio-Legal Aspects of the 3D Printing Revolution", Springer Science and Business Media LLC, 2016

Ankita Bhavsar, Shashank Dhar Tiwari, Kuldeep Vinchurkar, Rohit Doke, Koushlesh Mishra, Ankita Badoriya, Priya Jain. "Chapter 9 Economic and Market Trends in FDM 3D Printing for Pharmaceuticals", Springer Science and Business Media LLC, 2025